BD9G201UEFJ-LBE2

ActiveDC/DC CONV, BUCK, 500KHZ, 105DEG C ROHS COMPLIANT: YES

Deep-Dive with AI

Search across all available documentation for this part.

BD9G201UEFJ-LBE2

ActiveDC/DC CONV, BUCK, 500KHZ, 105DEG C ROHS COMPLIANT: YES

Deep-Dive with AI

Technical Specifications

Parameters and characteristics for this part

| Specification | BD9G201UEFJ-LBE2 |

|---|---|

| Current - Output | 1.5 A |

| Frequency - Switching | 300 kHz |

| Function | Step-Down |

| Mounting Type | Surface Mount |

| Number of Outputs | 1 |

| Operating Temperature [Max] | 105 ░C |

| Operating Temperature [Min] | -40 C |

| Output Configuration | Positive |

| Output Type | Adjustable |

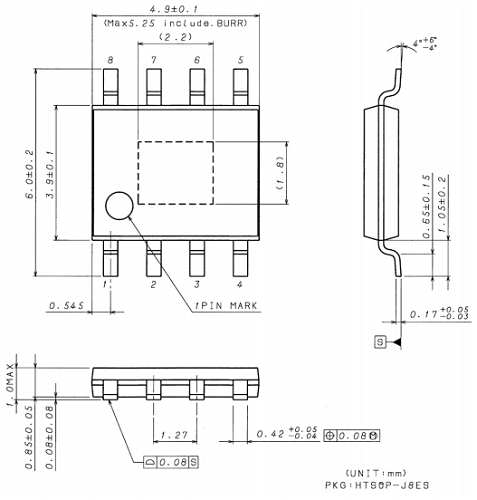

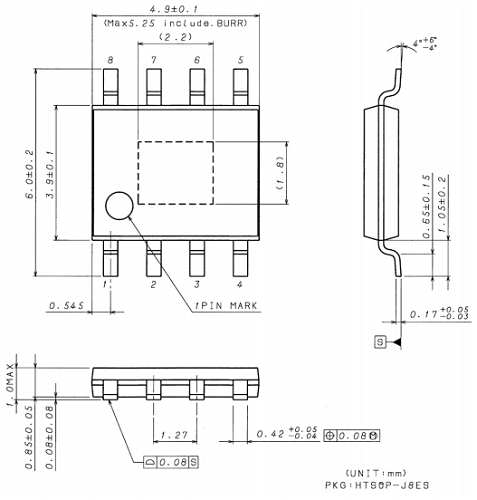

| Package / Case | Exposed Pad, 8-SOIC |

| Package / Case [x] | 0.154 in |

| Package / Case [y] | 3.9 mm |

| Supplier Device Package | 8-HTSOP-JES |

| Synchronous Rectifier | False |

| Topology | Buck |

| Voltage - Input (Max) [Max] | 42 V |

| Voltage - Input (Min) [Min] | 4.5 V |

| Voltage - Output (Max) [Max] | 42 V |

| Voltage - Output (Min/Fixed) | 0.8 V |

Pricing

Prices provided here are for design reference only. For realtime values and availability, please visit the distributors directly

| Distributor | Package | Quantity | $ | |

|---|---|---|---|---|

| Digikey | Cut Tape (CT) | 1 | $ 2.09 | |

| 10 | $ 1.87 | |||

| 25 | $ 1.77 | |||

| 100 | $ 1.51 | |||

| 250 | $ 1.41 | |||

| 500 | $ 1.24 | |||

| 1000 | $ 1.03 | |||

| Digi-Reel® | 1 | $ 2.09 | ||

| 10 | $ 1.87 | |||

| 25 | $ 1.77 | |||

| 100 | $ 1.51 | |||

| 250 | $ 1.41 | |||

| 500 | $ 1.24 | |||

| 1000 | $ 1.03 | |||

| N/A | 0 | $ 1.92 | ||

| Tape & Reel (TR) | 2500 | $ 0.88 | ||

| Newark | Each (Supplied on Cut Tape) | 1 | $ 3.09 | |

| 10 | $ 1.99 | |||

| 25 | $ 1.70 | |||

| 50 | $ 1.53 | |||

| 100 | $ 1.35 | |||

| 250 | $ 1.19 | |||

| 500 | $ 1.08 | |||

| 1000 | $ 0.99 | |||

Description

General part information

BD9G201 Series

BD9G201UEFJ-LB is a buck converter with built-in high side MOSFET. It has an input voltage range of 4.5V to 42V. Current mode architecture provides fast transient response and a simple phase compensation setup. The IC is mainly used as a secondary side power supply: for example, a step-down output of 3.3V/5V can be produced from voltage power supply such as 12V or 24V. In addition, it has a synchronization function with an external CLK that provides noise management.This IC uses different production line against series model BD9G201EFJ-LB for the purpose of improving production efficiency. We recommend using this IC for your new development. Electric characteristics noted in Datasheet does not differ between Production Line. In addition, the data of BD9G201EFJ-LB is disclosed for documents and design models unless otherwise specified.

Documents

Technical documentation and resources