Catalog

Precision MEMS IMU Module

Key Features

• Triaxial, digital gyroscope±125°/sec, ±500°/sec, ±2000°/sec dynamic range models2°/hr in-run bias stability (ADIS16465-1)0.15°/√hr angular random walk (ADIS16465-1 and ADIS16465-2)±0.05° axis to axis misalignment error

• ±125°/sec, ±500°/sec, ±2000°/sec dynamic range models

• 2°/hr in-run bias stability (ADIS16465-1)

• 0.15°/√hr angular random walk (ADIS16465-1 and ADIS16465-2)

• ±0.05° axis to axis misalignment error

• Triaxial, digital accelerometer, ±8 g3.6 μg in-run bias stability

• 3.6 μg in-run bias stability

• Triaxial, delta angle, and delta velocity outputs

• Factory calibrated sensitivity, bias, and axial alignmentCalibration temperature range: −40°C to +85°C

• Calibration temperature range: −40°C to +85°C

• SPI-compatible data communications

• Programmable operation and controlAutomatic and manual bias correction controlsData ready indicator for synchronous data acquisitionExternal sync modes: direct, pulse, scaled, and outputOn demand self test of inertial sensorsOn demand self test of flash memory

• Automatic and manual bias correction controls

• Data ready indicator for synchronous data acquisition

• External sync modes: direct, pulse, scaled, and output

• On demand self test of inertial sensors

• On demand self test of flash memory

• Single-supply operation (VDD): 3.0 V to 3.6 V

• 2000 g mechanical shock survivability

• Operating temperature range: −40°C to +105°C

Description

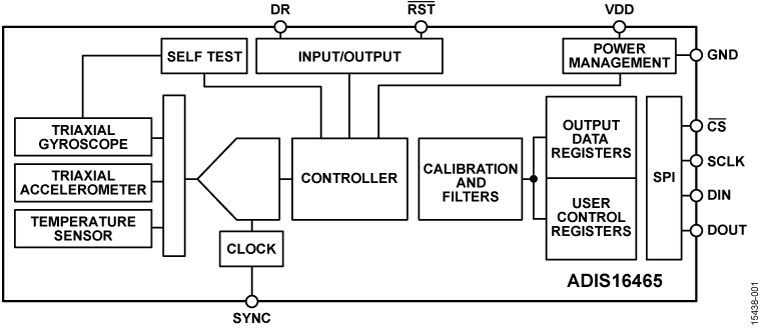

AI

The ADIS16465 is a precision, microelectric mechanical system (MEMS), inertial measurement unit (IMU) that includes a triaxial gyroscope and a triaxial accelerometer. Each inertial sensor in the ADIS16465 combines with signal conditioning to optimize dynamic performance. The factory calibration characterizes each sensor for sensitivity, bias, alignment, linear acceleration (gyroscope bias), and point of percussion (accelerometer location). Therefore, each sensor has dynamic compensation formulas that provide accurate sensor measurements over a broad set of conditions.The ADIS16465 provides a simple, cost effective method for integrating accurate, multiaxis inertial sensing into industrial systems, especially when compared to the complexity and investment associated with discrete designs. All necessary motion testing and calibration are part of the production process at the factory, greatly reducing system integration time. Tight orthogonal alignment simplifies inertial frame alignment in navigation systems. The serial peripheral interface (SPI) and register structure provide a simple interface for data collection and configuration control.The ADIS16465 is in an aluminum module package that is approximately 22.4 mm × 22.4 mm × 9 mm with a 14-lead connector interface.ApplicationsNavigation, stabilization, and instrumentationUnmanned and autonomous vehiclesSmart agriculture and construction machineryFactory/industrial automation, roboticsVirtual/augmented realityInternet of Moving Things